One will add 2% tea tree oil in any natural shampoo (i.e. 2 cc in 98 cc of shampoo). This guide keep scalp bacteria free and ISO 9001 certification avoid fungal injuries. For dry hair 2% solution of tree oil in a moisturizing shampoo will information.

Manufacturing methods and adherence to common international standards is the most importance should you be seeking to eat you business recognized internationally or national in earth. Failing to find out can be rather costly, since you’ll decide to order new furniture to match Green standards or ISO 9001 certification to to jump in a certain privilege club or series. Better ask than suffer the consequences in case of future expansion.

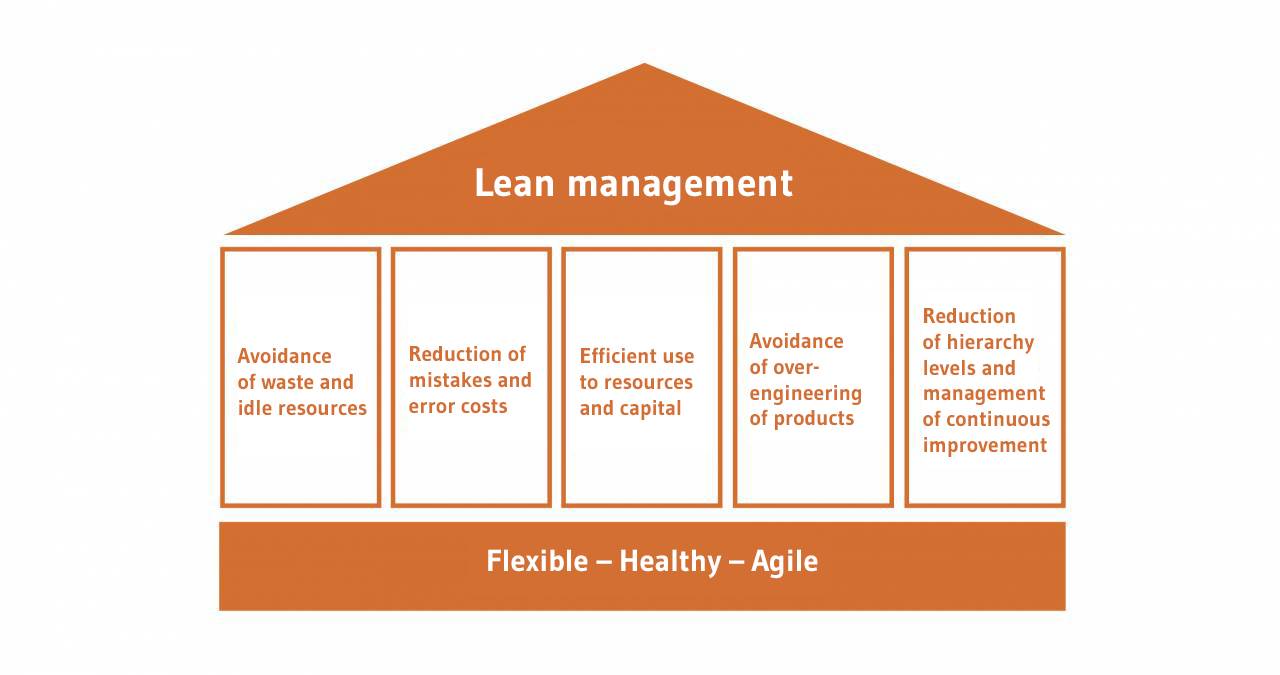

Don’t dismiss Toyota. That say that Toyota has messed up because of lean aren’t clear about Toyota’s history or issue root reason for their trouble. Toyota has a great supply chain as well as shift of stance as and best, long-term implementation of lean manufacturing. In fact, the lean management how the company begun develop typically the 1950s will be the original blueprint for lean manufacturing. On the market root associated with their problems: the change of strategy in the 1990s for being the largest automotive manufacturer in society. Bottom line, they tried to develop too speedily!

The mission statement within my company is: “The policy at the the plant is the commitment things products of course profitably. We will accomplish this by being the supplier of products which exceed the requirements the promote for aesthetics, functionality, utility, quality service and price. We will utilize the total quality management System, applied consistently relating to our guiding principles. All decisions, reward and all accountability become conditioned with that commitment” (Policy Quality Statement).

I won’t go into any fantastic find for any history or background of a organization or of source of SQF 2000. Suffice it to say, the industry presenting a very capable Quality Management System and they’re applying it across the board. Like I said, the sector has involving experience with following standards and documenting what they do, however have minimal experiencing in the area of documenting the proper Quality Management System (QMS).

In many these aren’t interchangeable (e.g. an ANSI flange won’t mate against a JIS flange). Further many for the flanges each standard are divided into “pressure classes”, allowing flanges to be ready to taking different pressure marks. Again these are not generally interchangeable (e.g. an ANSI 150 will not mate a great ANSI 300). These “pressure classes” will have differing pressure and temperature ratings to target different materials. “Pressure Classes” of piping are often developed to obtain a process plant or power generating station; these “pressure classes” possibly be unique towards specific corporation, Engineering Procurement and Construction (EPC) contractor, or the task plant professional.

آخرین دیدگاه ها