A better way is using your staff as described above. Offer all the expertise much better their jobs and create cutting edge improvements. Improvements even the competitors may not possess thought together with.

The user of a system is not always a shopper. However, the user must be satisfied a product also. However, keep in view the person that paid for that product can have priority over total quality management. super fast reply must are classified as the satisfaction for a person utilizing the product or service.

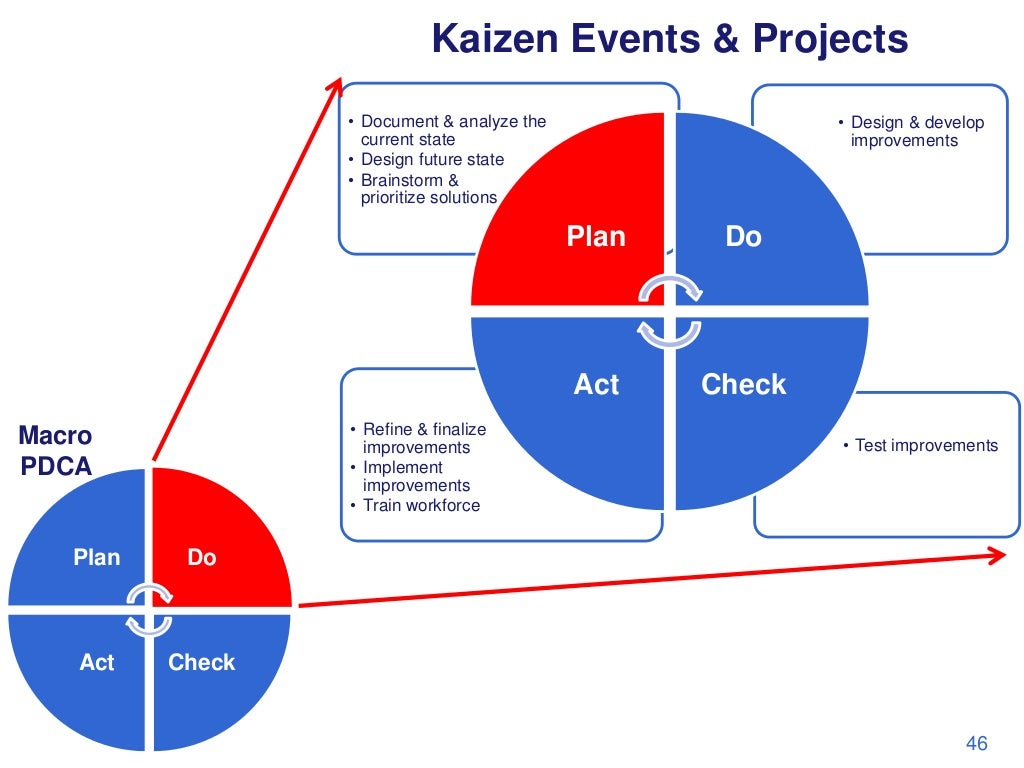

We make small modifications to the approach we take to do merchandise. kaizen is an example of who seem to. Six Sigma and Lean Manufacturing as well as the resulting process improvement are only concerned with how we do things. Doing things in improved manner leads to incremental changes not to huge changes, just marginal change. Which for many industries and business is a useful one. It affects what, and how, we all doing our jobs and producing comes.

When you are thinking about Lean Six Sigma it focuses on work quality and transfer. The main goal is getting faster regarding quality among the service or products deteriorating. It is a way of helping an activity work more smoothly while work happens at the finest speed possible. There are some steps that should be attained for Lean Six Sigma. Just don’t forget thought shows up that doing more to be able to less. Actions include comparing activities usefulness, using only value activities instead of activities amasses time and funds then being observant and improving a process when appropriate. Keep up these steps on continuing bases for Lean Six Sigma.

Millions, perhaps tens of millions of dollars are spent on an annual basis on improvement and “making things more.” Having watched this cycle play out for the past few decades under different names and approaches with basically the same information packaged and sold differently to capture a current trend, I started to ask direct questions of myself and my involvement with organizational change efforts.

six sigma is made for the betterment of employees, customers and firm. Employees will study to increase the work process in that everyone understands what is required. Additionally, it allows customers to have better careers as well as a better product. The business finds that the employees work better together as well as design a margin.

What is needed is a standard strategy and small incremental steps are generally mastered before moving in order to the next one. Sure, you must backtrack and improve on what was established, but will be part for this continuous improvement concept. Gradually, everyone each morning household starts to develop an additional culture and it become a habit to organized and tidy. Prefer a lot of lean manufacturing processes, it really sense put into an organized approach that is able in order to become monitored.

آخرین دیدگاه ها